The important features of the membrane switch

1, small and light: general membrane switch weight for a few grams to dozens of grams, very easy to carry and disassemble;

2, beautiful: modern perfect screen printing technology, with the perfect design, you can make any pattern you need;

3, sealing: the use of unique technology, can make the membrane keypad switch with waterproof, anti-oil, anti-pollution, anti-static interference and other functions;

4. Excellent conductive performance: the circuit of the switch can be printed with carbon paste, silver paste, copper and platinum, and the conductive layer can be folded at will; And the resistance can be controlled in any resistance you want to need, and, using a unique technology, the membrane switch can even accept tens of thousands of volts of high voltage electric shock without damaging its function;

5, low cost: some membrane keyboard switch selling price even only a few cents, relative to a has so many functions of the electronic raw device products, its price advantage is not other similar products can achieve.

6, long service life: because the membrane switch used by the material has good insulation, heat resistance, flexibility and high resilience; And the printing of the pattern are printed on the reverse side, so that the silk screen pattern will not be damaged; Therefore, the service life of the membrane switch can generally reach more than three years.

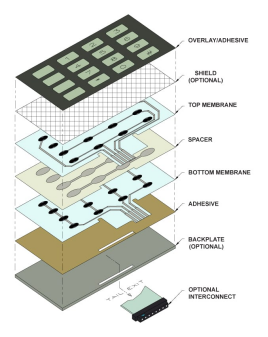

Common membrane switch disassembly and assembly diagram:

Common membrane switch components of the material

First, the panel layer

The panel layer is generally less than 0.25MM PET, PC and other colorless transparent sheet screen printing on the fine pattern and text production, because the most important role of the panel layer is to play the role of identification and keys, so the selection of materials must have high transparency, high ink adhesion, high elasticity, anti-bending characteristics.

Two, rubber layer

The most important role of the cushion layer is to closely connect the panel layer with the circuit layer, so as to achieve the effect of sealing and connection. The thickness of this layer is generally required to be between 0.02- 0.05MM, with high viscosity and anti-aging; In the production, the general selection of special film switch double-sided adhesive, some film switch requirements can waterproof and high temperature, so the rubber layer must also be used according to the needs of different properties of materials.

Three, control circuit upper and lower

This layer adopts good performance polyester film (PET) as the carrier of switching circuit graphics and on it with a special process silkscreen silver pulp carbon pulp or gold pulp to make it conductive, its thickness is generally within 0.05--0.175MM, the most common is 0.125MM PET

Four,Laminated layer

It is between the upper circuit and the lower circuit layer and plays the role of sealing and connecting, generally using PET double-sided adhesive, its thickness is 0.05-0.2mm; When selecting this layer of material, the overall thickness of the product, insulation, feel of the circuit key package and tightness should be fully considered.

Five, back rubber layer

The use of adhesive and membrane switch and what kind of material is closely related to the paste, the common double-sided adhesive, 3M adhesive, waterproof adhesive and so on.

Keypad switch, panel material, in addition to the requirements of flatness and printing adaptability, more important is to have the characteristics of flexibility and high elasticity.

Types of materials

PVC\60℃\0.175~0.5/ smooth \ stable to acid, base and salt at room temperature. Good wear resistance, fire resistance, noise and shock, good electrical insulation. Poor thermal stability.

Polycarbonate PC\-60~120℃\0.175~1.0\ smooth surface high transmittance, low water absorption, good dimensional stability, bending, tensile, compressive strength is very superior, heat resistance and cold resistance, electrical insulation and atmospheric aging resistance excellent. Drug resistance is poor, fatigue resistance is poor, easy to produce stress cracking, output interface terminal circuit is generally printed with carbon material, and no protective coating, by air oxidation gradually formed off layer, to finally lead to the end of the life, this is the film switch most prone to failure, mainly determined by the environment, whether used or not, Physical damage time is 3-10 years. Generally applicable to the most extensive range, in addition to meet the requirements of most membrane switch panel, which smooth PC high transmittance can also meet the requirements of a liquid crystal display window.

Sand surface polyester (PET)\-30~120℃\0.1~0.2 smooth surface \ good drug resistance, insoluble in general organic solvents, no alkali resistance. With excellent mechanical properties, electrical properties, rigidity, hardness and thermoplastics in the largest strength and toughness, low water absorption, wear resistance, good friction resistance, high dimensional stability. Tensile strength can be comparable to aluminum film, much higher than PC, PVC. Low because the surface is difficult to process into matte type, textured PET is more expensive is the most ideal substrate for making film switching circuit. Textured PET is suitable for products with high surface requirements or liquid crystal display Windows.

Thickness of material

The thickness of the plastic substrate is 0.25mm and below known as the film, mainly used as the film switch panel layer, its back printed with a variety of indicative patterns, text to indicate the operation area of the corresponding switch key, the thickness of the selection should depend on the size of the panel and the key, the thickness of the material, increase the touch force, slow response; The material is too thin, feel poor when touching, bounce back is not obvious. Thickness of 0.25mm above called plate, not suitable for three-dimensional key forming, can be used as no key operation area of the indicator sign panel, can also be used as a film switch lining board to improve its hardness.

Line layer printing material:

The substrate for making the circuit should be polyester (polyethylene glycol phthalate) film (Potyester for short PET). It has good insulation and heat resistance, high mechanical strength, transparency and air tightness, especially with flexibility and high elasticity, is the ideal material for making film switching circuit.

membrane switching structure

1) Flat non-tactile type:

Long service life, but no touch;

2) Convex touch type of film:

Good touch, but relatively short service life;

3) Convex frame type non-tactile type:

Beautiful appearance, there is a strong three-dimensional sense, but no sense of touch;

4) Convex frame touch type:

Beautiful appearance, strong three-dimensional sense, and touch;

5) Face plate convex touch type:

(a) type: when the design is not appropriate, it is easy to have two sections, but the surface is damaged, and the electrical performance is also there;

(b) type: there is no two-section phenomenon, and the structural layer is less, more economic, if the plate is damaged, electrical performance will not exist;

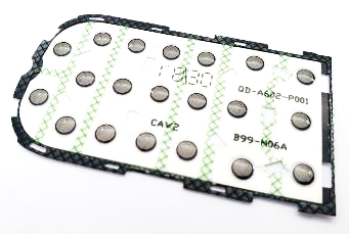

6) Metal shrapnel type:

Type (a) : is the most basic and most commonly used structure. Shrapnel acts both as a touch and as a wire;

Type (b) : Complex structure, used for shrapnel more dense and do not have jumper occasions. Shrapnel on the line on the road, the conductive surface of the upper and lower lines are up, the line needs to punch. This structure is conductive when the four feet of the shrapnel and the center point is not in the same plane, there are "two sections" of the situation. At the same time, the shrapnel is often in excessive concave strong state, for a long time, the shrapnel will not rebound phenomenon, not recommended;

(c) type: shrapnel on the line on the line, only touch the role, the upper line conductive face down, the lower line conductive face up, there are "two sections" of the case, not recommended;

(d) type: shrapnel is placed on the lower line, the upper and the lower line are wired, shrapnel both plays the role of touch and play the role of connecting the upper and lower lines; Used for more shrapnel, more dense and do not have jumpers, the structure is simpler than (b) type. The design should pay attention to the line to avoid the four legs of the shrapnel, to ensure that there is no short circuit.

7) Luminous body type: be sure to open the bottom rubber mold;

(a) LED line and the line under the same layer: simple structure, but the LED window should be convex, otherwise, the LED light will top the surface version; It is suitable to choose the height of the small LED lights or LED lights less occasions;

(b) LED line and the lower line of different layers: the structure is complex, but the LED window does not have to be convex, suitable for the use of two-color LED lights or LED lights a large number of occasions; Need to open punching die and bottom rubber die;

8) Anti folding:

This type can avoid jumper and do not need to fill holes can make the conductive surface can be downward, the structure of the shortcomings in the fold is easy to break the line.

9) Waterproof inside and outside frame type:

The outer frame is a closed frame with no wire running, and the inner frame plays a protective role to prevent water and air from entering the housing from the outlet groove.